FEATURES

The atomizer is powered by the air source of the air compressor. The vacuum self priming primer is applied to make the liquid atomized through the nozzle and air, and then sprayed to the lubrication point of the workpiece, cutter or bearing. Cooling effect is good, and provide lubrication, chip removal, cleaning and other functions, in order to improve production efficiency and processing quality, reduce the loss of mechanical tools, reduce workshop pollution.

1. Cooling, lubricating and blowing iron chips can be completed at one time during the processing.

2. It can improve cutting speed, save processing time and reduce tool wear.

3. It can ensure the quality of workpiece finishing and the best use effect of cutting tools.

4. Processing alloys or superhard materials can also achieve a smooth and high-precision surface.

5. Increasing the sealing method can avoid internal oil leakage and prolong the service life.

6. The volume of the sprayer and the coolant can be adjusted to facilitate the use of different processing conditions.

7. There are different fixing ways to choose, in order to facilitate the installation and fixing of customers.

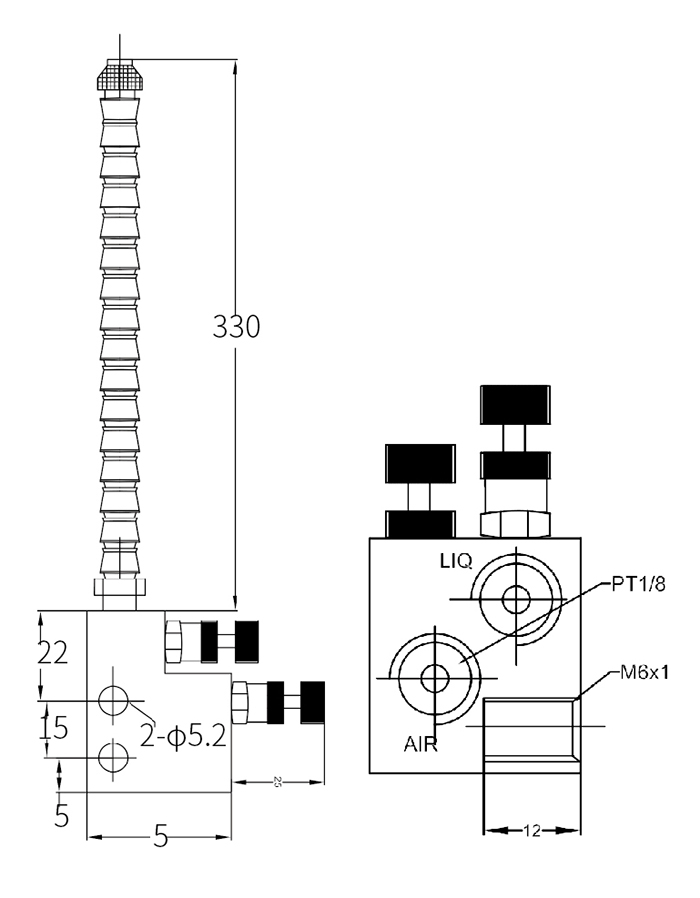

SPECIFICATIONS