FEATURES

Product Overview

AGP100 electric lubrication pump uses DC motor driving force for reciprocating oil absorption and drainage of plunger pump. The power supply uses DC24V power supply. The oil drum provides 2L and 4LPc transparent plastics. It can be divided into two types, i. e. pressure plate type and agitation type. The pressure plate type is pressurized by taper spring and can work in inversion and rotation. AGP100 electric lubrication pump controller has built-in pressure switch, counting, alarm signal output of low oil level sensor. Two plunger pumps with displacement of 2.5cc/min are installed. External installation of safety valve, pressure up to 30 MPa AGP100 electric lubrication pump and the company’s progressive distributor (ASV) constitute a progressive lubrication system, but also with the company’s single-line distributor (ASL) form a single-line lubrication system for centralized lubrication. The pump is mainly used in wind power, construction machinery and other industries.

Working principle

The eccentric cam on the motor shaft is driven by 24V DC motor to rotate, so that the plunger pump on the compressed cam can move in a reciprocating straight line_and then complete the two processes of oil suction and oil drainage. The plunger pump has a one-way valve, so that the oil discharged can not be reversed.

Single line lubrication system

The single-line centralized lubrication system with ED controller works periodically. The grease provided by the lubrication pump is measured by the single-line distributor. At the same time, the lubrication points are injected for NLG 1, 2. The grease is suitable for wind power, gold treatment, power, port, lifting, woodworking, engineering machinery and other equipment.

Progressive lubrication system

The progressive centralized lubrication system is equipped with LED controller, and the progressive distributor is gradually injected with high-pressure grease according to the progressive type. NLGl-1#, 2#.

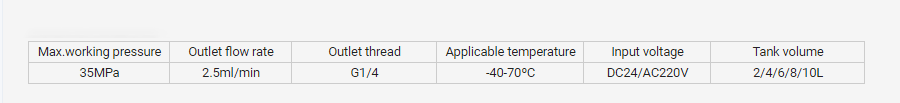

SPECIFICATIONS

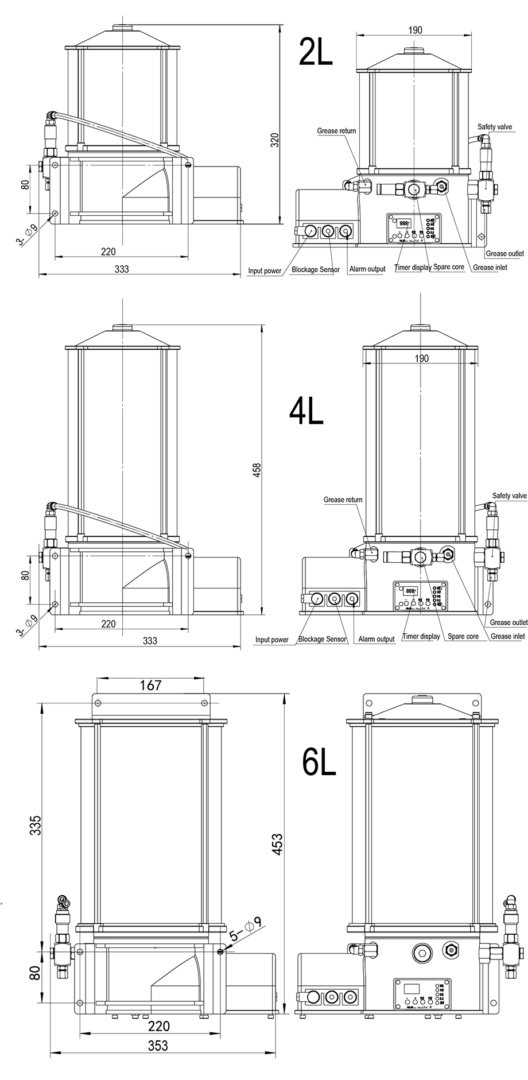

DIMENSIONS